Liquid Waste Management

Read the Magazine in PDF

Abstract

The liquid waste management in healthcare facilities highlights the various sources, sewage treatment plant (STP) processes, and essential considerations. The liquid waste originates from diverse healthcare activities, from patient care to diagnostic procedures, surgeries, and general hospital operations.

Effective management of this waste is crucial for environmental safety and regulatory compliance. The article delves into the intricate workings of STPs, outlining their multi-stage treatment processes. From preliminary and primary treatments involving debris removal and settling tanks to advanced secondary and tertiary treatments, such as biological processes and disinfection, each step aims to produce treated water meeting regulatory standards. Furthermore, the article explores the sewage and sullage composition, the significance of biochemical oxygen demand (BOD), and chemical oxygen demand (COD) in sewage quality assessment. Lastly, it is important to emphasise the criticality of sludge disposal, discussing digestion and subsequent drying bed treatment for sludge reuse as organic fertilizer, adhering to environmental guidelines.

Introduction

Liquid waste generated in hospitals can come from various sources within the healthcare facility.

Some common sources include:

- Patient Care Activities: Fluids used for patient care, such as bodily fluids (blood, urine, and excretions), irrigation fluids, dialysis fluids, and wound irrigation solutions.

- Laboratory and Diagnostic Procedures: Chemical reagents, solutions, and fluids used for diagnostic testing, such as blood tests, cultures, and analyses.

- Operating Theatres and Surgical Procedures: Waste generated during surgeries, including used irrigation fluids, cleaning solutions, and other surgical fluids.

- Radiology and Imaging Departments: Fixer and developer solutions, contrast agents, and other chemicals used in imaging processes.

- Pharmaceutical and Drug Administration: Expired, unused, or contaminated medications and solutions, including intravenous fluids and drug preparation residues.

- Housekeeping and Cleaning Activities: Wastewater from cleaning and disinfection processes, floor washing, and equipment sterilization.

- Kitchen and Food Services: Wastewater from kitchen activities, including food preparation, dishwashing, and cleaning.

Proper management of liquid waste from these sources is crucial to prevent environmental

contamination, ensure compliance with regulations, and protect public health. Treatment and disposal of liquid medical waste often involve specialized processes to minimize environmental impact and potential health risks.

Sewage treatment plant (STP)

A sewage treatment plant (STP) is a facility designed to treat wastewater or sewage from residential, commercial, and industrial sources before it released back into the environment.

The primary goal of an STP is to remove contaminants, pathogens, and pollutants from

sewage to produce treated water that is safe for disposal or reuse.

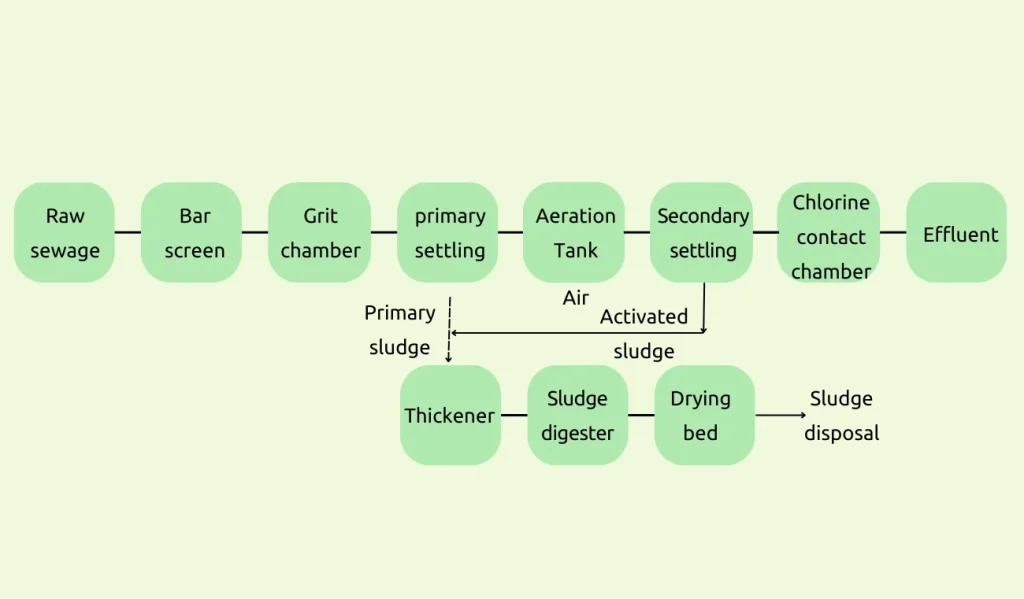

The process in an STP involves several stages:

- Preliminary Treatment: Large debris, solid materials, and grit are removed through physical processes such as screening to prevent damage to downstream equipment.

- Primary Treatment: The sewage enters settling tanks were suspended solids settle at the bottom as sludge, while grease and oil float to the surface, forming scum. This step removes a significant portion of solids and some organic matter.

- Secondary Treatment: Biological processes are used to further treat the wastewater. Microorganisms break down organic matter in the sewage through aeration tanks, activated sludge processes, or biofilters. This stage significantly reduces the organic content and pollutants.

- Tertiary Treatment: Advanced treatment methods are employed to further improve the quality of the treated effluent. Processes like filtration (sand or membrane),disinfection (chlorination, UV radiation), or nutrient removal (phosphorus, nitrogen) are used to ensure the water meets required standards.

- Sludge Treatment: Any sludge generated during the treatment process undergoes further treatment. This includes thickening, digestion to reduce its volume and pathogen content, dewatering to remove excess water, and sometimes incineration or use as fertilizer.

The treated water, also known as effluent, is then discharged into water bodies or reused for

non-potable purposes like irrigation or industrial processes. Sewage treatment plants play a crucial role in protecting public health, preserving the environment, and conserving water resources by ensuring the safe disposal or reuse of wastewater.

Scheme as per BMW rules, 2016

Sewage and Sulage

Sewage is waste water from a community, containing solid and liquid excreta, derived from houses, street and yard washing, factories and industries.

The term sullage is applied to waste water which does not contain excreta, e.g. waste water from kitchen and bathrooms.

Composition of sewage

Water: 99%

Organic and inorganic solid: 0.1%

One gram faeces may contain about 1000 million E.Coli, 10-100 million faecal streptococci, and 1-10 million spores of Cl. Perfringens.

Decomposition of organic matters

Aerobic process: In the presence of oxygen organic matter is broken down into CO2, water, ammonia, nitrites, nitrates and sulfates by action of bacterial action including fungi and protozoa.

Anaerobic process: Anaerobic bacteria decompose organic waste into methane, ammonia, co2 and H2.

AIM of a sewage plant

To stabilize the organic matter so that it can be disposed off safely and to convert the sewage water into an effluent of an acceptable standard of purity which can be disposed of in to land, rivers or sea.

A standard test which is an indicator of the organic content of the sewage is biochemicaloxygen demand (BOD).BOD is defined as the amount of oxygen absorbed by a sample of sewage during specified period, generally five days, at a specific temperature, generally by living organism.

BOD value ranges from 1mg/liter for natural water to 300mg/liter for untreated sewage. Chemical oxygen demand (COD) is a test that measures the amount of oxygen required to chemically oxidize the organised material and inorganic nutrients, such as ammonia or nitrate, present in water. The permissible limit of COD is 250 to 500ppm.

Screening

Sewage first passed through metal scree to remove large floating objectives such as pieces of woods, rags, plastics paces, masses of garbage and dead animals.

GRIT Chamber

After screen sewage is then passed through a long narrow chamber called as grit chamber or detritus chamber.

The chamber is about 10-20 meter and velocity of sewage flow is about 1 foot per second taking a detention period of 0.5-1minute.

The grit chamber allows to settle down heavier solids such as sand and gravel while permitting the organic matter passing through. The grit collected at the bottom of chamber is removed periodically or continuously.

Primary sedimentation

After passing through sewage is then admitted to a huge rectangular tank called as primary sedimentation tank. Sewage is made to flow very slowly across the tank at a velocity of 1-2 feet/minute and retained 6-8hours in tank. Nearly 50-70% organic solids settled down due to gravity. The sludge is removed mechanically operated devices and subjected to sludge dryer. Due to biological action certain treatment takes place. Scum at the uppermost layer should be removed periodically.

Secondary sedimentation

The effluent from the primary sedimentation tank still contains a proportion of organic matters in solution and numerous living organism. It has high oxygen demand and subjected to further treatment ‘aerobic oxidation’ by one of the following methods: Trickling bed filter method Activated sludge process

Activated sludge process

Subjected to aeration chamber for aeration for 6-8hours. The aeration is accomplished by either mechanically agitation or by forcing compressed air continuously from the bottom of aeration tank. The organic matter of the sewage gets oxidized into CO2, nitrates and water with the help of aerobic bacteria.

Chemical disinfection

To inactivate pathogens in wastewater.

Several choices are as follows: Free chlorine and combined chlorine UV Ozone Chlorine dioxide

Ultra-filtration

Ultrafiltration is a water treatment process that uses a hollow fiber or sheet membrane to mechanically filter water containing very small particulate. An ultrafiltration drinking water system uses this super fine membrane technology to filter particulate down to 0.025.

A UF system can filter most solid particulates in fluids, but cannot filter out dissolved particulate like RO plant. It can filter out inorganic solids, viruses, and bacterial because of their sizes.

Sludge disposal

3-4 weeks complete digestion takes place and it is carried out in sludge drying bed. Digested sludge is used as organic fertilizer for agricultural purpose.

Conclusion

In essence, the comprehensive overview of liquid waste management within healthcare facilities underscores its diverse sources and the pivotal role of sewage treatment plants (STPs) in ensuring effective waste treatment. The article meticulously details the spectrum of waste origins, spanning patient care, diagnostics, surgeries, and hospital operations, emphasizing the necessity for stringent waste management protocols to safeguard the environment and align with regulatory mandates.

The delineation of STP intricacies, encompassing various stages from initial debris removal and primary treatment to advanced biological and disinfection processes, underscores the concerted effort to produce treated water meeting stringent regulatory criteria. Additionally, the exploration of sewage and sullage composition, along with the evaluation of biochemical oxygen demand (BOD) and chemical oxygen demand (COD), highlights key parameters vital for sewage quality assessment.

Crucially, the discourse culminates by underlining the significance of proper sludge disposal methods. The discussion on sludge digestion and subsequent drying bed treatments, aimed at repurposing sludge as organic fertilizer while adhering to environmental directives, amplifies the holistic approach toward sustainable waste management practices in healthcare settings.

The collective insights elucidated within this article underscore the complexity of liquid waste management in healthcare, advocating for a meticulous approach that integrates various treatment processes and emphasizes responsible waste disposal methods.

References

- Module 23: Management of healthcare wastewater

- Guidelines for management of healthcare waste as per biomedical waste management rule, 2016.

Author

-

Consultant FMS, Rajagiri Hospital, Aluva, Consultant & Head,VBG consulting engineers, Aluva