Protection of UPS & electrical panels

READ AS MAGAZINE PDF

Protection of Critical Electrical Equipment/Panels

There are many types of Electrical Cabinets within an organization, and they are there to maintain and control all kinds of vital processes throughout the business. Whether they are Machinery Control Cabinets (MCCs), Switchgear, Substations or simple Fuse Boxes, they are vital to the continued operation of a business and the loss or damage of such a piece of equipment could have devastating consequences.

- Fire is one of the major causes of damage to these items of essential equipment and the ability to prevent such losses, through simple fire protection engineering can mean the difference between business success and failure.

Fire Risks & Downtime:

Typically fires in electrical panels start from loose connections and faulty wires, when there is power running through them the electricity can ark. This arced electricity is extremely hot and causes the plastic coatings on the wires to burn and spread to other components.

One thing to note is that low-voltage and high-voltage connections and equipment are both fire risks and deserve equal amounts of protection. By running the tubing directly above any connections and components such as switches and transformers you will minimize the time it takes to detect and suppress the fire.

Financial Loss, Operational Downtime or even the destruction of your operation can be a frightening reality, with around 40% of all organisations experiencing a fire, never recovering.

Impact of Small Fires

A small fire starting in a low-cost electrical cabinet can spread and cause millions of dollars worth of incremental damage.

A Fire of this nature can impact the whole operation of a business and cause serious life safety issues. Small Fires can lead to huge damage and cost.

Protecting Electrical cabinets with a low-cost but highly effective Tube Based Protection System can be part of a responsible Fire Risk Reduction program inside an organization.

Damage Without Fire Protection

There was a recent incident of a burnt-out MCC at a location in Europe which did not have any automatic in-cabinet fire protection. It was a control cabinet for vital functions within this company’s operation. The loss through downtime and affected stock was considerable. Though the smoke alarm was triggered by the time the fire brigade could extinguish the fire the damage had been done. An engineer on-site tried to tackle the fire with a handheld portable extinguisher but the smoke and flames and the enclosure around the burning components meant that he was unable to affect the fire in any way.

Can this be avoided?

With a Tube-Based Automatic Fire Detection and Suppression System:

- This fire would already be out!

- Firetrace Systems have been installed on thousands of electrical control cabinets all over the world for high or low-voltage enclosures

- Firetrace Systems are ideal for the early detection and protection against fire in these environments, being automatic, clean and safe for use on electrical equipment and with a choice of system sizes available, able to protect many different types of application.

- The Firetrace Systems used on electrical control cabinets consist of a small, pressurized container using either FM200 or 3M™ Novec™ 1230 as the extinguishing medium.

- This is connected to a length of Firetrace Detection Tube (FDT) that is appropriately routed all around the compartment(s) to provide linear, pneumatic detection in a 360 degree environment

- In the event of a fire, or high temperature rise, the FDT will burst and discharge the extinguishing agent directly on to the fire at its source, rapidly knocking down any fire.

- The agent quickly fills the compartment, rapidly knocking down the flame and suppressing the fire within a matter of seconds.

- Suppression is by means of cooling, with some chemical reaction with the flame and both types of agent are clean, non-toxic and confirmed as suitable for use on electrical fires

SYSTEM ARCHITECTURE

Fire trace Detection Tubing is ideal for fire detection in electrical control cabinets, as it is treated just like another cable. It is electrically non-conductive, flexible, easy to install and will not affect any rating of the cabinets and their compartments. It is also suitable for use in all environments, be they clean or dusty and is not affected by high airflow or low temperatures. Following a system discharge, no clean-up of the agent is required, as they are clean, non-toxic gases when discharged in a fire situation.

Should you be unlucky enough to experience a fire in your equipment, you’ll find you can be operational in only a short space of time. By only having to maybe repair a small part of your unit and with the simple re-charging or replacement of your Fire trace system, you can be up and running, with full protection in no time, ensuring any business interruption is kept to a minimum.’

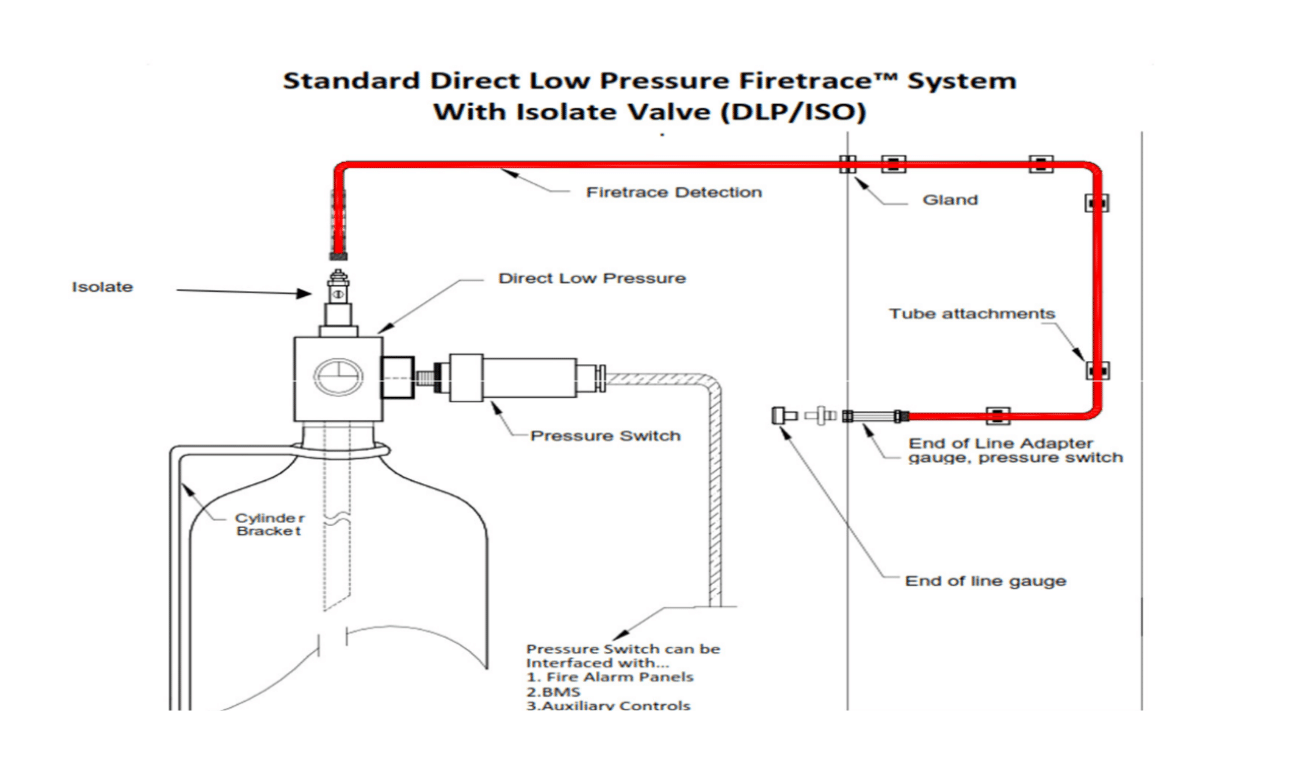

DIRECT LOW-PRESSURE SYSTEM SAMPLE DRAWING

The primary cause of the fire may be due to the short circuit /overheating of certain components in the panel board. Since most of the Panel areas are unmanned and completely closed, the fire inside the panel is not visible and accessible from the outside till it becomes too big, dangerous and unmanageable.

The Fire Protection System envisaged for electrical panel’s call for early detection of fire and quenching the same by localised flooding of the electrical panel with Novec 1230 fire-extinguishing liquid besides giving out an audio-visual alarm.

The main features of the system are:

- Automatic Detection of Fire.

- Automatic flooding of NOVEC 1230.

- Activation of Audio-visual Alarm unit.

The detection of fire is primarily made by FIRE TRACE TUBE, which can detect fire anywhere along its length. The tube is highly flexible and can be conveniently routed to cover the various hazard areas in electrical panels.

The FIRE TRACE Tube is a fixed temperature sensing tube made up of high-tech polymer material to cater to long-term leak resistance, flexibility, and accurate and consistent heat sensitivity. One end of the FIRE TRACE Tube is connected to the NOVEC 1230 2KG Container and the other end to an End of Line Adapter through a Non-return valve.

A Pressure Switch is connected to the End of Line Adapter, which is electrically connected to an audio-visual Alarm Unit.

In the event of fire contacting the FIRETRACE Tube, the Tube starts melting and bursts at the hottest point. This will make the Valve fitted on the Novec 1230 container open instantaneously and the Novec 1230 liquid stored in the container will get released through the Tube at the bursting point into the panel.

The Fire trace Units can be used, but are not limited, to protect the following:

- Telecommunication areas

- Electrical and electronic cabinets

- Data Processing areas and cabinets

- Other high-value assets.

- Laboratory fume /exhaust cabinets

- Other high-value assets.

- Laboratory fume /exhaust cabinets

- Pump enclosures

- UPS units

- Flammable Chemicals storage cabinets

- Generator Enclosures

- Transformer Cabinets

- Computer/Data Storage Cabinets

- CNC & VMC Machining centers

- Many other applications

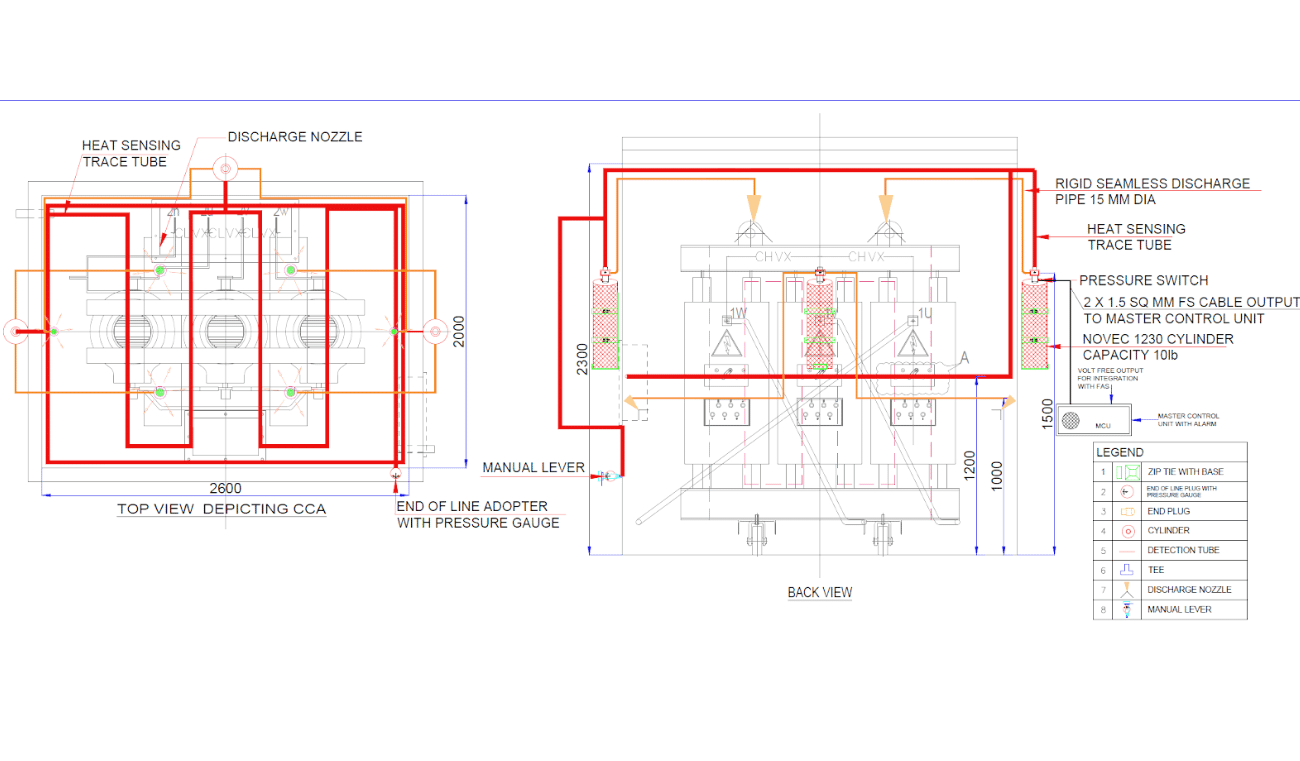

INDIRECT LOW-PRESSURE SYSTEM SAMPLE DRAWING

The system utilizes unique Fire trace flexible tubing that is attached to the top of the cylinder valve. This tubing is pressurized with dry nitrogen, is temperature-sensitive, and acts as a continuous linear thermal detector that ruptures upon flame impingement. Once the detection tubing is ruptured, it forms a nozzle at the rupture point, allowing the Novec 1230 agent to flow through, distributing the extinguishing agent through the nozzle into the protected area. Upon system actuation, the pressure switch can be used to indicate system discharge, shutdown ventilation, shut-off electrical power, etc. as may be required.

IS 12456 -Fire Protection of Electronic Data Processing Installation and National Building Code – Part 4 Fire & Life Safety recommend the use of Fire Detection and Fire Protection Systems for protecting all types of Electronic Data processing units, Emergency Power Equipment like HT Panels, LT Panels, Transformers, Lift Panels and all other electrical Equipment’s.