High-Pressure Water Mist

READ AS MAGAZINE PDF

Introduction

The high-Pressure water mist system, an innovative water-based firefighting solution, has been developed extensively over the last 30 years. Conventional firefighting systems remain the main technique for fixed firefighting installations globally. This development of the new technology was driven by taking into consideration the drawbacks of sprinkler systems and gas-based systems. Water mist firefighting today has achieved a well-established position in fire protection and it has become an accepted alternative solution for a large number of applications.

Here we would like to highlight the various applications which can be protected in a hospital and pharma industry environment.

Principle

Water is the most effective cooling agent to fight fires. Conventional water-based systems require large quantities of water to control/extinguish fires, mainly making use of the cooling effect. Due to the large use of water, the majority of the water is not effectively used to fight the fire resulting in large water run-off. This is due to the limited surface area of the water droplet getting into contact with the heat of the fire.

If water is atomized into very fine droplets, as it is with water mist technology, a substantially larger surface area is available to absorb energy, resulting in effective firefighting capability. Additionally, to the cooling effect, the fast vaporization results in a local inerting effect by a volume increase of water resulting in oxygen depletion in the direct vicinity of the fire. This is a major difference from other inerting agents where the oxygen concentration of the entire space is not affected but only at the source of the fire.

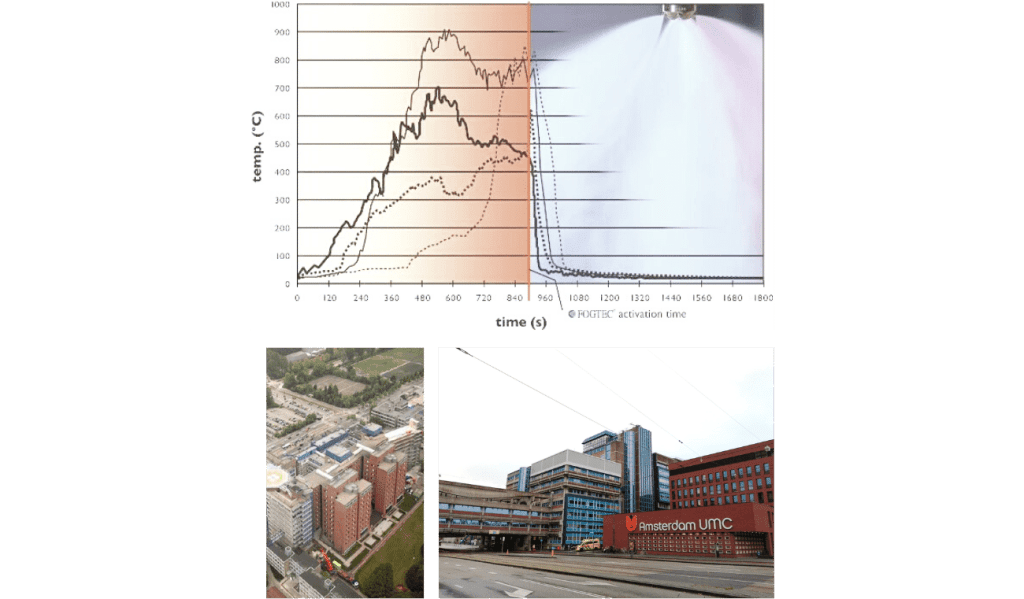

Fire test

Water Mist System cannot be designed like a conventional sprinkler system or Gas based system, which is based on two-dimensional water calculations. For each application, the required nozzle type, droplet distribution, Flow rate and discharge time have to be individually determined to provide the optimum protection of the relevant risk. Protocols for light and ordinary hazard risk applications have been established by Factory Mutual (FM 5560 standard) and CEN(CEN/TS 14972 standard). Utilizing these guidelines, the application-specific design parameters are generated and systems components are approved. For each application, the necessary test fire is simulated along with the fire experts based on which the parameters are defined.

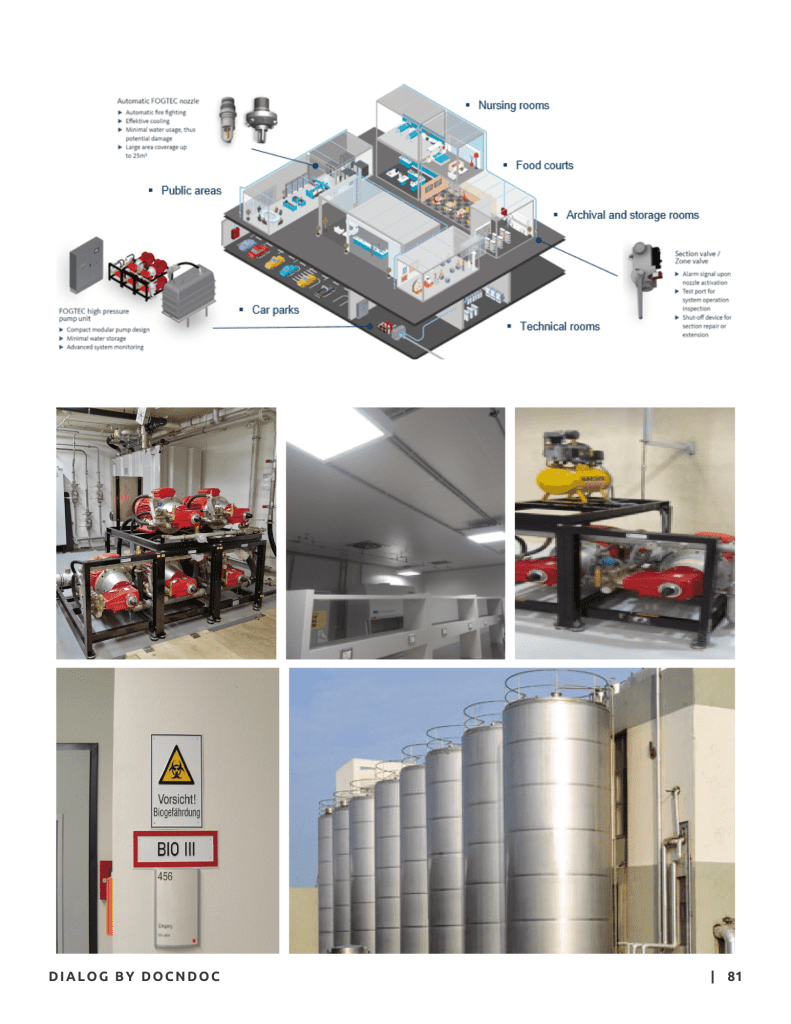

System Set-up

A high-pressure water mist system mainly consists of high-pressure generating devices, high-pressure pipelines and special nozzles. The required operating pressure is generated by means of high-pressure pumps or pressure cylinder systems. The selection depends on the type of risk and the area to be protected. Larger risk areas such as archives, libraries, Hospitals and museums are normally protected by pump systems. The main design features of high-pressure pump units are similar to conventional sprinkler pumps, whereby positive displacement pumps are used due to the high-pressure levels required.

A high-pressure water mist system utilizes minimal water compared to the conventional sprinkler system. Therefore, the storage tank sizes are 10% of the size of conventional sprinkler systems.

Case Study

In Hospitals, the operators are afraid of large water usage of conventional sprinklers due to water damage to valuable electric equipment and to areas not directly affected by a potential fire. This is where a High-pressure water mist system provides a unique solution by utilizing minimal water, which is approximately 70-80% less, compared to the conventional sprinkler system. In addition, there is minimal impact on electronic components.

Water Mist System was proposed and installed in University Hospital in Amsterdam. A few of the challenges are mentioned below the project:

- Pipework and system installation under the full operation of the hospital

- Continuous coordination with the client

- Reduction of onsite presence to a minimum level

- The high degree of pipe pre-fabrication

- Local pipe routing adjustments by pipe bending

- Press fittings for the highest reliability and quiet installation

- No use of scaffolding or other construction equipment

Based on the above challenges Water Mist System was proposed and accepted by the management. As this was a retrofit project looking at the space constraint and installation hassle Water Mist System proved to be an ideal solution due to the compactness of the equipment (Pumps and Break Tanks) and the use of 25mm Stainless Steel distribution pipes which will have negligible impact on hospital structure and low maintenance.

Bio-Safety Laboratory

The field of biotechnology has experienced rapid growth over the past twenty years. Worldwide, new methods have expanded the potential of traditional biotechnology. Modern processes often involve the manipulation of living cells as well as biochemical reactions with living cells or cell components.

It is always paramount to avoid any potential danger to humans, animals and the environment. Several laws, regulations and guidelines must be observed when constructing and operating laboratories with biosafety levels S1 to S4.

The following additional precautions must be observed:’

- The safety of employees must be ensured at all times

- A fire in a laboratory must be safely extinguished

- Laboratory enclosures must be sealed off

- Laboratories must be maintained with a subatmospheric pressure and proper ventilation

- Toxic fumes must be prevented from escaping into the environment

- Run-off of water into the environment must be kept to a minimum

- Fire-fighting personnel may not be exposed to additional hazards

- The water used to extinguish the fire must be properly collected and thermally or chemically neutralized

Water Mist System was proposed and installed in International Centre for Foot & Mouth Disease (ICFMD) in Bhubaneswar, India.

CFMD is a prestigious R&D facility of ICAR with a BSL3+ laboratory & Animal Experiment Facility for conducting biomedical research in the area of Foot and Mouth Disease. This facility shall also serve as a regional resource Laboratory for SAARC countries.

Areas Protected:

- Lab areas

- Stores

- MAL Room

- Storeroom inflammable

- De-contamination loading room

- Central instrumentation room

- DNA room

- Virus purification room

- Toolroom

- Cell culture

- ABSO room

- Lab meeting room

Conclusion

Even if Water Mist systems initially were mainly seen as an alternative to gas extinguishing systems for machinery and special risk protection, more and more applications in areas that traditionally have been protected by conventional sprinklers are identified for water mist.

Due to the partially higher initial investment cost and lack of general design parameters, Water Mist systems will today not substitute sprinklers in most of the traditional applications but can be installed in critical applications like hospitals, archives, etc. where the benefits of water mist technology over conventional sprinklers or gas extinguishing systems are recognized by users and insurers.

Unlike conventional gas-extinguishing systems, a high-pressure water mist system ensures high safety in laboratories. Since it poses no danger to humans, the Water Mist System can be activated immediately on fire detection without pre-warning times. No excess atmospheric pressure is created, as is the case with conventional gas-extinguishing systems. Since the volume of water released is far less than with normal sprinkler systems, water retention and thermal or chemical neutralization are both less complicated and less expensive.